Our Production

All products of our wide range of quality equipment conform to the relevant regulations and standards, e. g. AD2000, ASME, BS etc.. The capacity of our two work shops allows us to manufacture vessels ranging up to 3,500 mm and more in diameter, as well as unit weights up to 35 tons and, on request even up to 80 tons.

A workforce of 30 experienced engineers and technicans is responsible for providing the complete scope of our supplies and services which include engineering, customer consulting, manufacture, inspection, packaging and shipment. A certified quality management system ensures the highest standard of product quality.

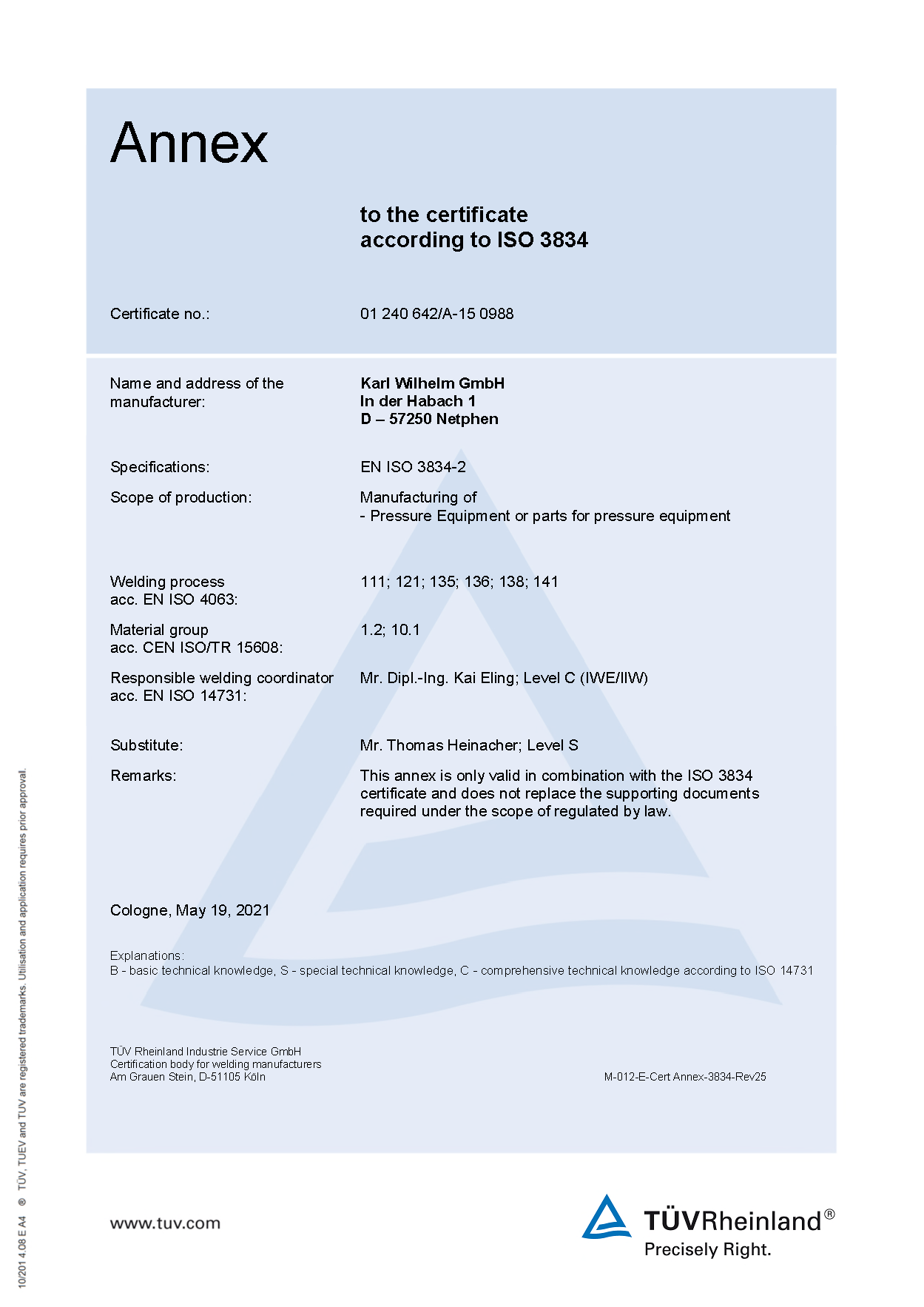

Our Welding Processes

Our qualified welding staff (DIN EN9606, EN14732 and ASME IX) applies state-of-the-art machining processes and latest welding technologies to ensure the best quality of your product.

At Karl Wilhelm we use amongst the common welding technologies (GTAW, FCAW, GMAW, SMAW) also modern processes such as Submerged arc welding (SAW), Electro-slag welding (ESW) and orbital welding.

This allows us to constantly comply with special mechanical and technological requirements of our clients and to satisfy individual customer requests, e.g. weld overlay cladding and cladding with metal sheet/plate.

Our Materials

We process, inter alia, the following material grades:

Wall thickness: from 3mm to 120mm.

Stainless steel and special material grades:

Wall thickness: from 3mm to 30mm.

We also process all equivalent ASME material grades (e. g. SA105N, SA516Gr.70, SA387CL22, A333 GR.6 / P22, SS304L, SS321, SS 316Ti etc.)

Thanks to a staff of highly skilled welders, fully qualified to the requirements of DIN EN ISO 9606, ISO 14732, we have the capability to execute welding works on a large variety of material combinations. Moreover, we provide the relevant welding procedure testing according to EN ISO15614 (DIN EN288).

Our Quality

We manufacture equipment in compliance with all relevant safety rules and quality regulations. Our company is DIN EN ISO 9001 certified.

Out products are certified by the following bodies:

LLoyd's Register

TÜV

TÜV Austria

Dekra